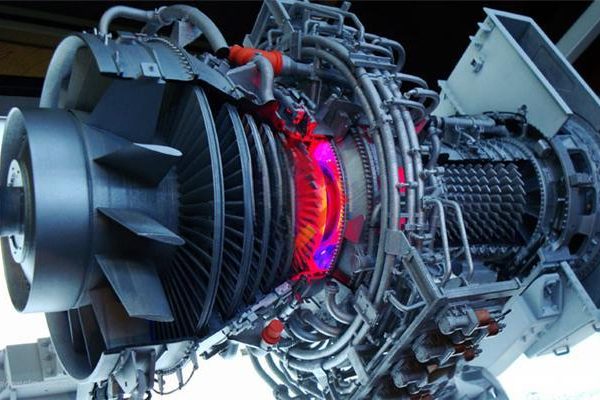

GH3536 alloy is a nickel-based high-temperature alloy with a high iron content, which is mainly strengthened by solid solution of chromium and molybdenum. The alloy has moderate permanent and creep strength below 900℃; it has good oxidation resistance and corrosion resistance, good cold and hot processing formability and welding performance. It is suitable for manufacturing parts such as combustion chambers of aircraft engines that are used for a long time below 900℃, and high-temperature parts that can be used for a short time at an operating temperature of up to 1080℃.

| Element | Minimum(%) | Maximum(%) |

|---|---|---|

| C | 0.05 | 0.15 |

| Cr | 20.5 | 23 |

| Ni | remiander | remiander |

| Co | 0.5 | 2.5 |

| W | 0.2 | 1 |

| Mo | 8 | 10 |

| Al | - | 0.5 |

| Ti | - | 0.15 |

| Fe | 17 | 20 |

| B | - | 0.01 |

| Cu | - | 0.5 |

| S | - | 0.015 |

| P | - | 0.025 |

| Si | - | 1 |

| Mn | - | 1 |

| Property | Value |

|---|---|

| Density | 8.28 g/cm³ |

| Melting range | 1295-1381 ℃ |

| Magnetism | None |

Copyright 2007 – 2024 |Shanghai Starway Metal Technology | All Rights Reserved | Powered by starway |