GH5188 is a Co-Ni-Cr based solid solution strengthened deformable high temperature alloy ,with a service temperature of less than 1100℃. 14% tungsten is added to the alloy for solid solution strengthening, which gives the alloy good comprehensive properties; a high content of chromium and trace amounts of lanthanum are added to give the alloy good high temperature oxidation resistance.

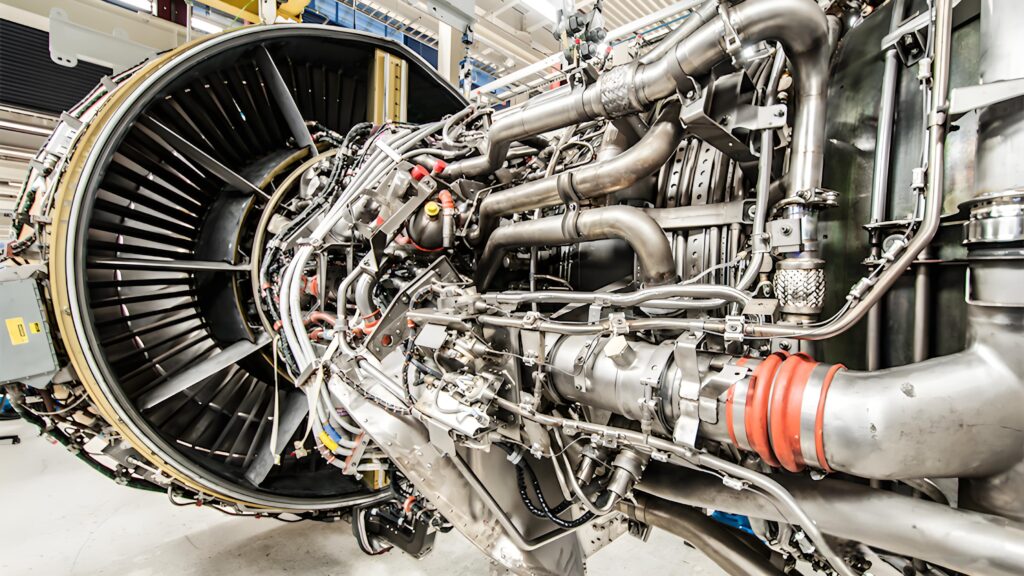

The alloy has good cold and hot processing plasticity and welding process properties, and is suitable for making aircraft engine parts that require high strength below 980℃ and oxidation resistance below 1100℃.

| Element | Minimum(%) | Maximum(%) |

|---|---|---|

| C | 0.05 | 0.15 |

| Cr | 20 | 24 |

| Ni | 20 | 24 |

| Co | remiander | remiander |

| W | 13 | 16 |

| Fe | - | 3 |

| B | - | 0.015 |

| La | 0.03 | 0.012 |

| Si | 0.2 | 0.5 |

| P | - | 0.02 |

| S | - | 0.015 |

| Cu | - | 0.07 |

| Ag | - | 0.001 |

| Bi | - | 0.0001 |

| Pb | - | 0.001 |

| Mn | - | 1.25 |

| Property | Value |

|---|---|

| Density | 9.09 g/cm³ |

| Melting range | 1300-1360 ℃ |

Copyright 2007 – 2024 |Shanghai Starway Metal Technology | All Rights Reserved | Powered by starway |