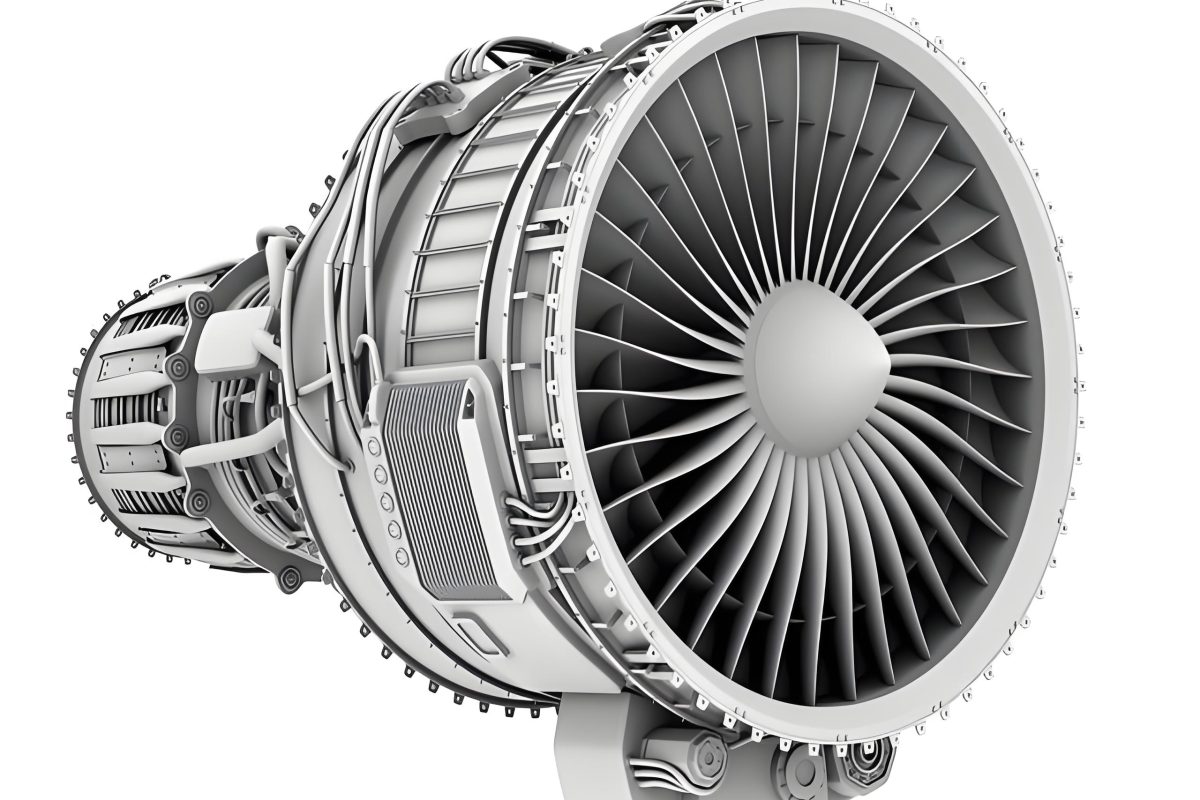

GH4738 is a nickel-based high-temperature alloy strengthened by γ’ phase precipitation. It has good gas corrosion resistance, high yield strength and fatigue performance, good process plasticity and stable structure. It is widely used in aircraft engine rotating parts, and the use temperature is not higher than 815℃. It can produce cold-rolled and hot-rolled plates, pipes, strips, wires, forgings, castings and fasteners.

| Element | Minimum(%) | Maximum(%) |

|---|---|---|

| C | 0.03 | 0.1 |

| Cr | 18 | 21 |

| Ni | remiander | remiander |

| Co | 12 | 15 |

| Mo | 3.5 | 5 |

| Al | 1.2 | 1.6 |

| Ti | 2.75 | 3.25 |

| B | 0.003 | 0.01 |

| Zr | 0.02 | 0.08 |

| Fe | - | 2 |

| Mn | - | 0.1 |

| Si | - | 0.015 |

| P | - | 0.015 |

| S | - | 0.1 |

| Cu | - | 0.001 |

| Property | Value |

|---|---|

| Density | 8.22 g/cm³ |

| Melting range | 1330-1360 ℃ |

| Coefficient of Linear Thermal Expansion | 12.47 x 10⁻⁶ ℃/K(at 20~100℃) |

This alloy is widely used in aviation engine gas turbines in the country, mainly as rotating parts such as turbine blades and turbine disks, and has mature experience in use.

Copyright 2007 – 2024 |Shanghai Starway Metal Technology | All Rights Reserved | Powered by starway |