GH901 is an austenitic age-hardening alloy based on Fe-43Ni-12Cr, with titanium, aluminum and equivalent strengthening elements added, and contains trace amounts of boron and relatively low carbon.

It is dispersed and strengthened by the metastable γ”[Ni3(Ti,Al)] phase, and trace amounts of aluminum can inhibit the transformation of γ” to η-Ni3Ti phase. The alloy has high yield strength and endurance strength below 650℃, good oxidation resistance below 760℃, and stable organization for long-term use.

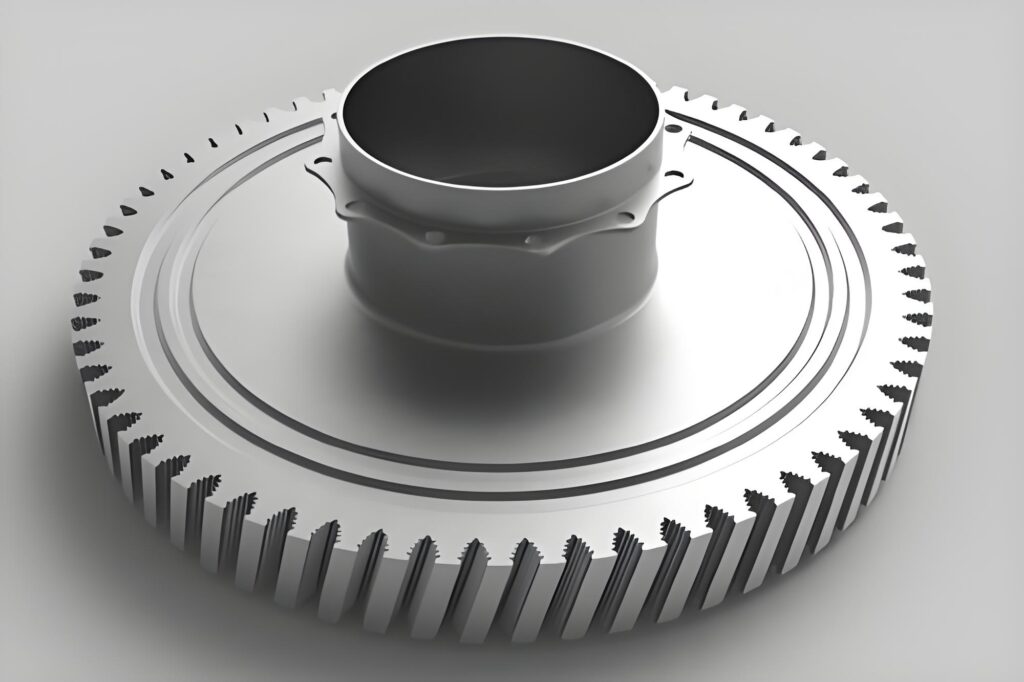

This alloy is a relatively mature alloy developed in the early stage, and is widely used in the manufacture of rotating disc parts (turbine discs, compressor discs, journals, etc.), static structural parts, turbine outer rings, fasteners and other parts of aviation and ground gas turbine engines working below 650℃.

| Element | Minimum(%) | Maximum(%) |

|---|---|---|

| Ni | 40 | 45 |

| Cr | 11 | 14 |

| Fe | remiander | remiander |

| C | 0.02 | 0.06 |

| Mn | - | 0.5 |

| Si | - | 0.4 |

| Mo | 5 | 6.5 |

| Al | - | 0.3 |

| Ti | 2.8 | 3.1 |

| Bi | - | 0.001 |

| P | - | 0.02 |

| Cu | - | 0.2 |

| Pb | - | 0.001 |

| B | 0.01 | 0.02 |

| S | - | 0.008 |

| Property | Value |

|---|---|

| Density | 8.21 g/cm3 |

| Melting range | 1360 ℃ |

| Coefficient of Linear Thermal Expansion | 13.5 x 10⁻⁶ ℃/K(at 20~100℃) |

| Thermal conductivity | 12.0 W/m•K(at 100℃) |

This alloy is widely used in foreign countries for rotating parts and fasteners working below 650℃ in aircraft engines and ground gas turbines, and has a long service life. It has also been used in aircraft engines in China and is a mature alloy that has been tested in use.

Copyright 2007 – 2024 |Shanghai Starway Metal Technology | All Rights Reserved | Powered by starway |