Incoloy800/800H/800HT

The Cr content in Incoloy800 alloy is usually 15-25%, the nickel content is 30-45%, and it contains a small amount of aluminum and titanium.

After rapid cooling from high temperature, 800 alloy is in the austenite single phase area, so the use state is a single austenite structure.

The alloy has a high chromium content and sufficient nickel content, so it has high high temperature corrosion resistance and is widely used in industry.

In chloride, low concentration NaOH aqueous solution and high temperature and high pressure water, it has excellent resistance to stress corrosion cracking, so it is used to manufacture equipment resistant to stress corrosion cracking.

Incoloy800/800H/800HT alloys have the same chemical composition except for the carbon content and up to 1% aluminum and titanium in 800AT alloy. 800 alloy is generally used in a temperature environment of about 593℃. 800H and 800HT alloys are usually used in a temperature environment of about 593℃ where higher creep and stress cracking resistance is required.

Content

Chemical composition of Incoloy800/800H/800HT(%)

| Incoloy800 | Incoloy800H | Incoloy800HT | ||||

|---|---|---|---|---|---|---|

| Element | Minimum(%) | Maximum(%) | Minimum(%) | Maximum(%) | Minimum(%) | Maximum(%) |

| Ni | 30 | 35 | 30 | 35 | 30 | 35 |

| Cr | 19 | 23 | 19 | 23 | 19 | 23 |

| Fe | remiander | remiander | remiander | remiander | remiander | remiander |

| C | - | 0.1 | 0.05 | 0.1 | 0.06 | 0.1 |

| Mn | - | 1.5 | - | 1.5 | - | 1.5 |

| Si | - | 1 | - | 1 | - | 1 |

| Cu | - | 0.75 | - | 0.75 | - | 0.75 |

| P | - | 0.03 | - | 0.045 | - | 0.02 |

| S | - | 0.015 | - | 0.015 | - | 0.01 |

| Al | 0.15 | 0.6 | 0.15 | 0.6 | / | / |

| Ti | 0.15 | 0.6 | 0.15 | 0.6 | / | / |

| Al+Ti | / | / | / | / | 0.85 | 1.2 |

Mechanical properties of Incoloy800/800H/800HT alloy

| Incoloy800 | Incoloy800H | Incoloy800HT | |

|---|---|---|---|

| Property | |||

| Density | 8.3 g/cm3 | 8.0 g/cm4 | 8.0 g/cm5 |

| Melting range | 1260-1355℃ | 1350-1400℃ | 1350-1400℃ |

Physical properties of Incoloy800/800H/800HT

| Incoloy800 | Incoloy800H | |

|---|---|---|

| Value | Property | Property |

| Elongation | 35% | 35% |

| Tensile Strength | 500 MPa | 450 MPa |

| Yield Strength (0.2% Offset) | 210 MPa | 180MPa |

Applications of Incoloy800/800H/800HT

Incoloy 800

Applications:

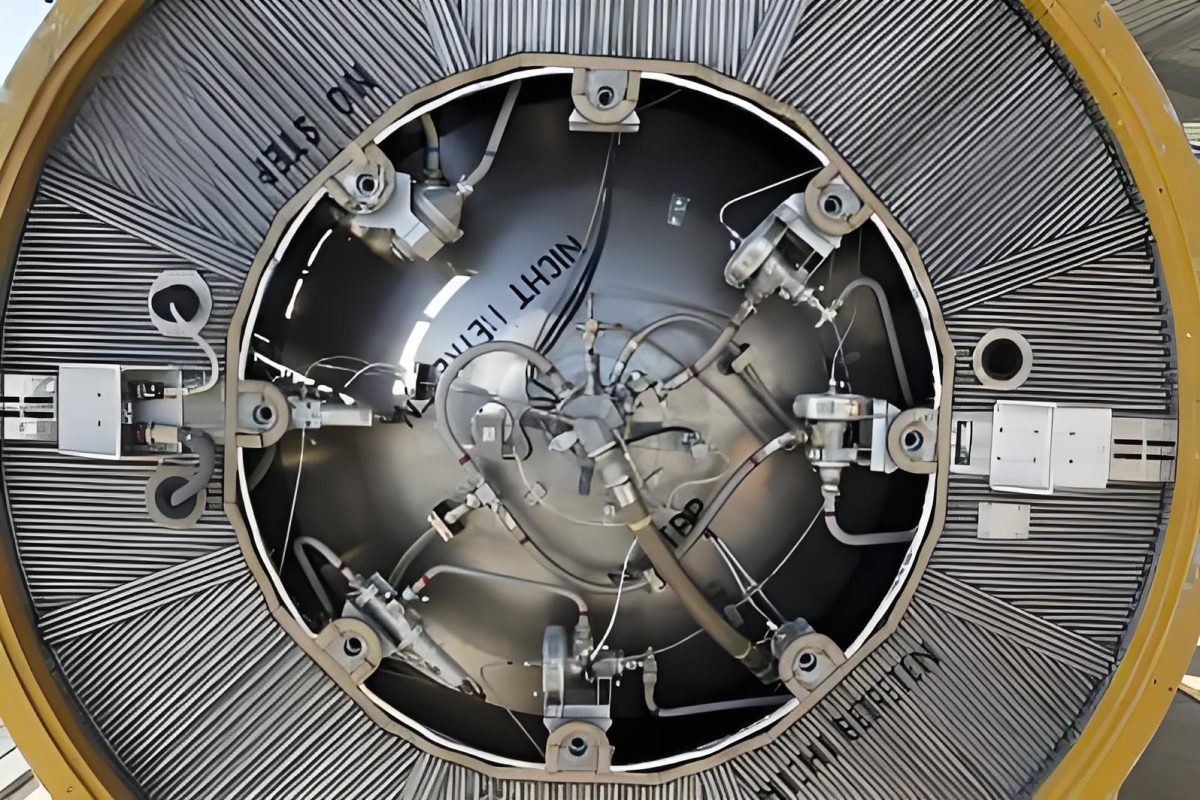

- Heat exchangers in chemical plants: Incoloy 800 is chosen for its excellent resistance to oxidation and carburization at high temperatures, making it ideal for heat exchange systems where organic and inorganic compounds are processed.

- Power generation: Its strong resistance to oxidation and stability under high-temperature atmospheres make it suitable for superheater and reheat tubes in power plants.

- Ethylene furnace quench boilers: The alloy’s ability to resist chloride-ion stress-corrosion cracking is beneficial in environments where petrochemical processing involves corrosive compounds.

Incoloy 800H

Applications:

- Industrial furnaces: The higher carbon content enhances its creep resistance, making Incoloy 800H ideal for components like furnace parts and fixtures exposed to prolonged high temperatures.

- Petrochemical processing: This alloy is used in equipment such as crackers and reformers in petrochemical plants due to its enhanced high-temperature strength and resistance to prolonged exposure to aggressive environments.

- Pressure vessels and heat exchangers: The increased temperature and pressure resistance of 800H make it suitable for high-pressure environments in chemical processing.

Incoloy 800HT

Applications:

- Equipment for heat-treating: Incoloy 800HT’s controlled carbon content and increased levels of aluminum and titanium provide excellent resistance to high-temperature corrosion, making it an excellent choice for fixtures and baskets in heat-treating applications.

- Power generation: Like 800H, 800HT is used in parts of power plants that require high creep resistance, such as in steam methane reforming furnaces for hydrogen production.

- Chemical processing: Its enhanced properties are beneficial in handling corrosive substances at high temperatures and pressures, making it ideal for applications such as reactor vessels and piping systems in chemical plants.

Each variant of the Incoloy 800 series is tailored to meet specific demands of high-temperature environments and corrosive conditions, with modifications in chemical composition focusing on optimizing performance for their intended applications.