Inconel 601

Inconel 601 UNS N06601 has excellent oxidation resistance at high temperatures, very good resistance to carbonization, can be very good oxidation resistance sulfur-containing atmosphere, at room temperature and high temperatures have very good mechanical properties very good resistance to stress corrosion cracking properties due to the control of the carbon content and grain size.

Inconel 601 has a high creep fracture strength, so in the field of 500 ℃ above the recommended use of Inconel 601.

Content

Chemical composition of Inconel 601(%)

| Element | Minimum(%) | Maximum(%) |

|---|---|---|

| Ni | 58 | 63 |

| Cr | 21 | 25 |

| Fe | - | remainder |

| C | - | 0.1 |

| Mn | - | 1.5 |

| Si | - | 0.5 |

| Cu | - | 1 |

| Al | 1 | 1.7 |

| P | - | 0.02 |

| S | - | 0.015 |

Physical properties of Inconel 601

| Property | Value |

|---|---|

| Density g/cm3 | 8.1 |

| Melting range ℃ | 1320-1370 |

Mechanical properties of Inconel 601 alloy

| Alloy Status | Tensile Strength Rm N/mm | Yield Strength RP0.2 N/mm | Elongation A5 % | Hardness HBW |

|---|---|---|---|---|

| Annealing treatment | 650 | 300 | 30 | - |

| Solid solution treatment | 600 | 240 | 30 | ≤220 |

Applications of Inconel 601

Inconel 601 (UNS N06601) is a nickel-chromium alloy known for its outstanding resistance to high-temperature oxidation and corrosion, making it suitable for a wide range of high-temperature applications. Here are some of its primary applications:

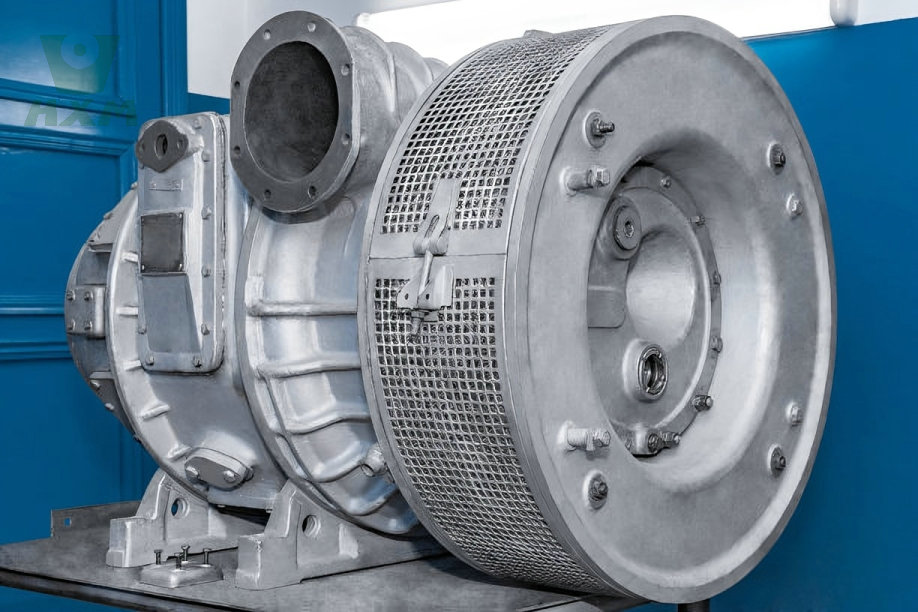

Industrial Furnaces:

- Inconel 601 is extensively used in industrial furnaces due to its ability to withstand high temperatures and oxidative environments. Components such as trays, baskets, and burners made from this alloy are common in heat-treating equipment.

Thermal Processing Equipment:

- This alloy is employed in equipment like muffles and retorts in heat-treatment plants. It maintains structural integrity and resists carburization even under cyclic thermal conditions.

Chemical Processing:

- Due to its corrosion resistance, Inconel 601 is used in reactors and vessels that deal with harsh chemicals, particularly those processes involving highly corrosive compounds at elevated temperatures.

Power Generation:

- It is used in boiler components and gas turbine components that must resist high-temperature corrosion and oxidation. The material’s properties help maintain efficiency and longevity in harsh operating conditions.

Aerospace Applications:

- Components like exhaust systems and engine components that must resist oxidation at high temperatures employ Inconel 601.

Pollution Control Equipment:

- The alloy is used in equipment designed to manage and control pollution, such as incinerators and thermal oxidizers where high-temperature resistance is crucial.

Petrochemical Industry:

- It is also utilized in catalyst regenerators and air preheaters in the petrochemical industry, where equipment often faces high temperatures and corrosive gases.

The versatility of Inconel 601 in high-temperature, corrosive environments makes it an ideal choice for these and other demanding applications.