7A09

7A09 belongs to the Al-Zn-Mg-Cu series super hard aluminum. This alloy has been used in the aircraft manufacturing industry since the late 1940s.

Ultra-high strength deformed aluminum alloy that is still widely used in the aviation industry. Its characteristic is that it has good plasticity after solution treatment.

The heat treatment strengthening effect is particularly good, with high strength below 150°C and particularly good low-temperature strength; poor welding performance; There is a tendency for stress corrosion cracking; it needs to be aluminum-clad or otherwise protected before use. Dual-stage aging can improve alloy resistance to stress corrosion cracking ability.

The plasticity in the annealed and freshly quenched states is slightly lower than that of 2A12 in the same state. It is slightly better than 7A04. The static fatigue of the plate. Notch sensitive, stress corrosion performance is better than 7A04.

Content

Chemical composition of 7A09(%)

| Chemicai composition | |

|---|---|

| Si | 0.5 |

| Fe | 0.5 |

| Cu | 1.2-2 |

| Mn | 0.15 |

| Mg | 2.0-3 |

| Cr | 0.16-0.3 |

| Zn | 5.1-6.1 |

| Ti | 0.1 |

| other impurity(singleness) | 0.05 |

| other impurity(sum) | 0.1 |

| AL | remainder |

Physical properties of 7A09

| Aluminum alloy grades and status | 7A09-T6 |

|---|---|

| Tensile Strength Rm/Mpa | 490 |

| Yield Strength Rp0.2/Mpa | 410 |

| Elongation % | 7 |

| Hardness/HBWα | 150 |

| Density(20℃)(g/cm3) | 2.9 |

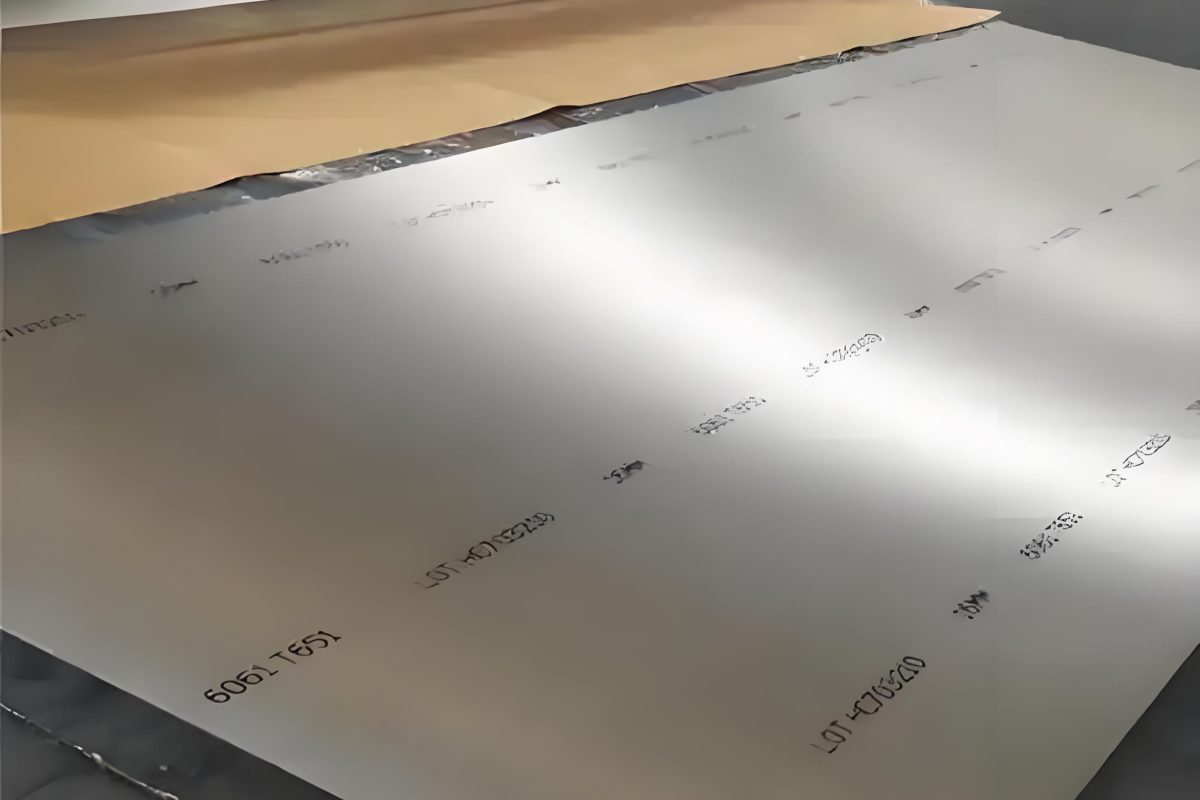

Applications of 7A09

7A09 is mainly used to manufacture aircraft structures and other high-stress structural parts that require high strength and corrosion resistance, such as on aircraft.Lower wing siding, stringers, etc. It has good plasticity after solution treatment, good heat treatment strengthening effect, and good strength below 150 degrees.It is also widely used in mold processing, mechanical equipment, tooling fixtures, aerospace industry, ultrasonic plastic welding molds, golf balls

Head, shoe mold, paper mold, foam mold, dewaxing mold, mechanical equipment, aircraft wall panels, front beams, joints, pillars and Structural parts such as landing gear, molds, beauty instruments, notebook casings, high-strength parts, heavy forgings and other fields.