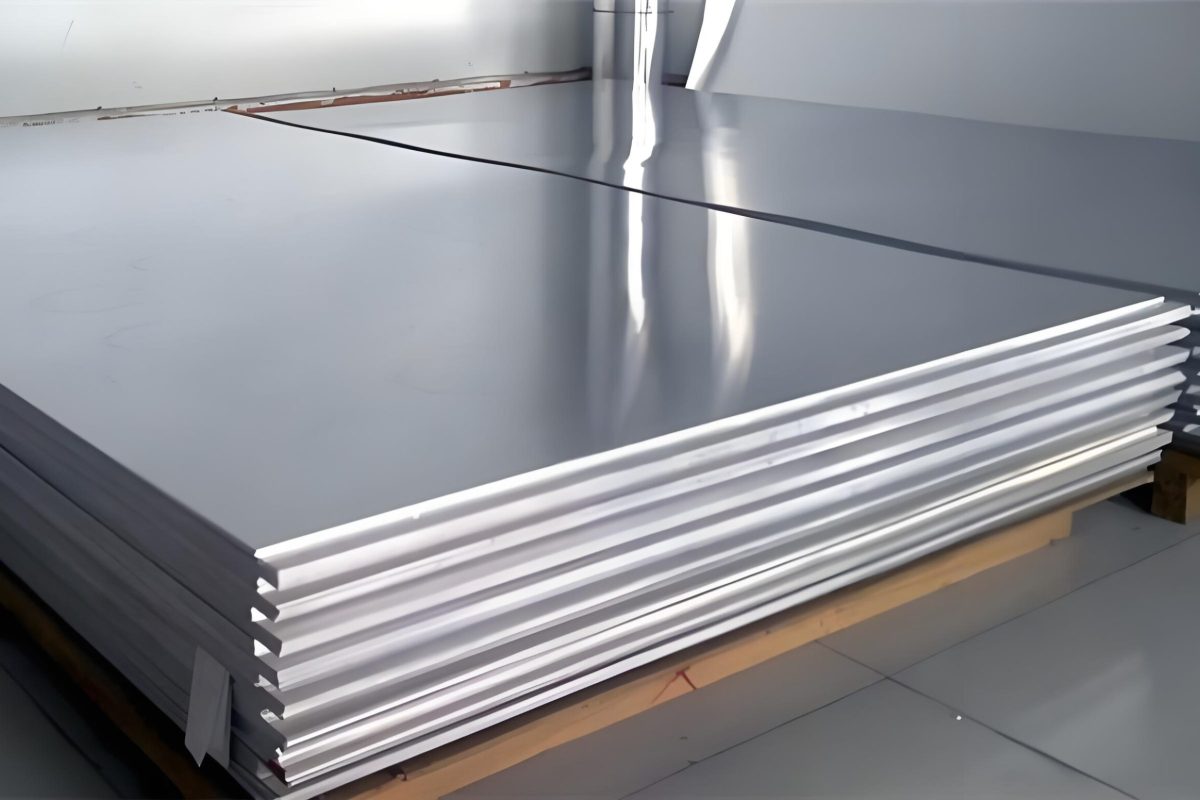

310S stainless steel is an austenitic chromium-nickel stainless steel with good oxidation resistance and corrosion resistance. Because of the higher percentage of chromium and nickel, it has It has much better creep strength and can continue to work at high temperatures. 310S stainless steel has good high temperature resistance. When the temperature exceeds 800 [1], it begins to soften and the allowable stress begins to continue to decrease. The maximum use Use temperature 1200℃.

Due to its high content of nickel (Ni) and chromium (Cr), it has good oxidation resistance, corrosion resistance, acid and alkali resistance, and high temperature resistance. High temperature resistant steel The tube is specially used for manufacturing electric furnace tubes and other occasions. After increasing the carbon content in austenitic stainless steel, the strength is improved due to its solid solution strengthening effect.

To improve the chemical composition characteristics of austenitic stainless steel, elements such as molybdenum, tungsten, niobium and titanium are added based on chromium and nickel. Since its structure is It has a face-centered cubic structure and therefore has high strength and creep strength at high temperatures.

| Element | Minimun % | Maximum % |

|---|---|---|

| Cr | 24 | 26 |

| C | - | 0.08 |

| Mn | - | 2 |

| Si | - | 1.5 |

| P | - | 0.03 |

| S | - | 0.045 |

| Ni | 19 | 22 |

| Tensile Strength σb MPa | ≥515 |

|---|---|

| Yield Strength σ0.2MPa | ≥205 |

| Elongation δ5% | ≥35 |

| Section shrinkage ψ (%): | ≥50 |

| Hardness: | ≤187HB |

Widely used in petroleum, electronics, chemical industry, medicine, textile, food, machinery, construction, nuclear power, aerospace, military industry and other industries.

Copyright 2007 – 2024 |Shanghai Starway Metal Technology | All Rights Reserved | Powered by starway |