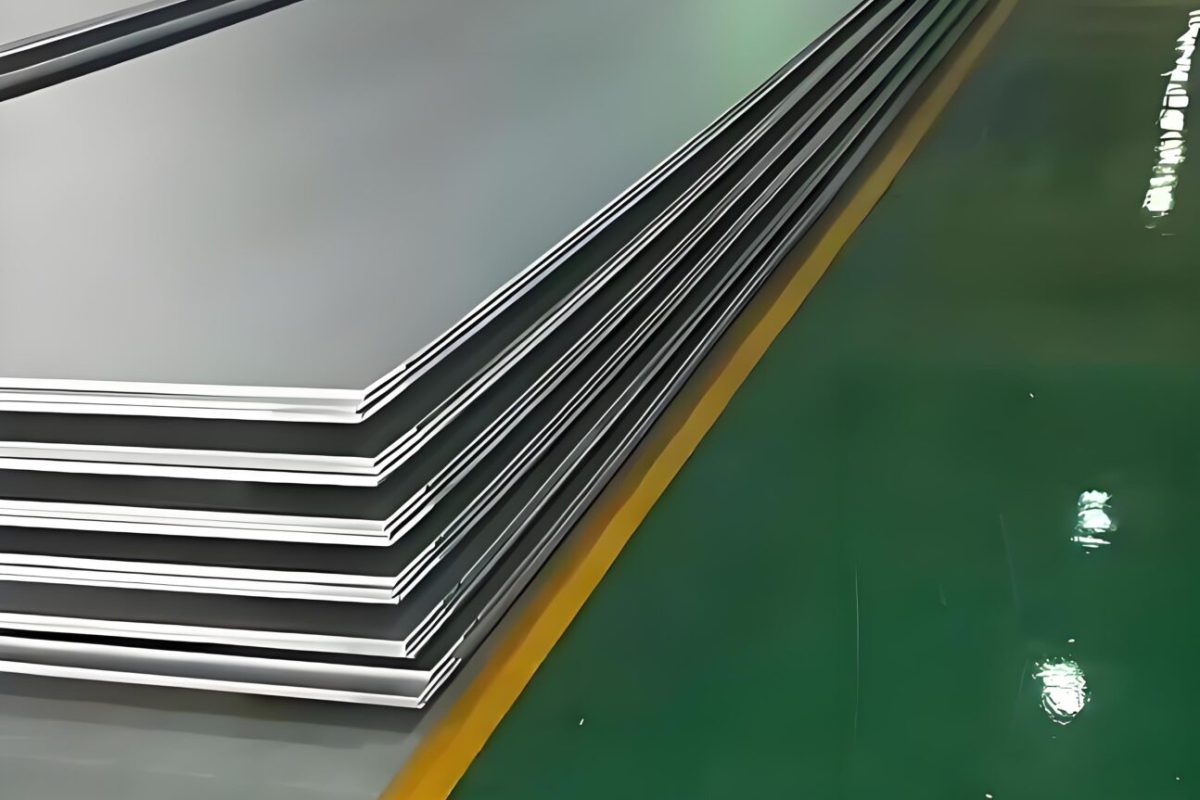

253MA is a heat-resistant austenitic stainless steel that requires high creep strength. Designed for applications with good corrosion resistance.

The chemical composition of 253MA is balanced, making the steel have the most suitable comprehensive performance in the temperature range of 850℃-1100℃, extremely high Excellent oxidation resistance, the oxide scale temperature is as high as 1150℃; extremely high creep deformation resistance and creep rupture strength; in most gas media It has good resistance to high temperature corrosion and brush corrosion; it has high yield strength and tensile strength at high temperatures; it has good formability and weldability, as well as sufficient machinability.

| Element | Minimun % | Maximum % |

|---|---|---|

| Cr | 20 | 22 |

| C | 0.05 | 0.1 |

| Si | 1.4 | 2 |

| S | - | 0..030 |

| Ni | 10 | 12 |

| N | 0.14 | 0.2 |

| Ce | 0.03 | 0.08 |

1) 253MA is widely used in sintering equipment, blast furnace equipment, steel Melting, furnace and continuous casting equipment, rolling mills (heating furnace), heat treatment furnace and accessories,

2) Mineral equipment and cement production equipment, etc.

3) 253MA steel can be used in pressure-bearing occasions and processes up to 900°C. For non-pressure high-temperature parts with temperatures up to 1150°C

Copyright 2007 – 2024 |Shanghai Starway Metal Technology | All Rights Reserved | Powered by starway |