GH3030 solid solution strengthened superalloy is an early developed 80Ni-20Cr solid solution strengthened superalloy with simple chemical composition, satisfactory thermal strength and high plasticity below 800°C, and good resistance to oxidation, thermal fatigue, Cold stamping and welding process performance. The alloy becomes single-phase austenite after solid solution treatment, and the structure is stable during use.

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Ni | Balance | Balance |

| Cr | 19 | 22 |

| Fe | – | 1.5 |

| C | – | 0.12 |

| Mn | – | 0.7 |

| Si | – | 0.8 |

| S | – | 0.02 |

| P | – | 0.03 |

| Al | – | 0.15 |

| Ti | 0.15 | 0.35 |

| Property | Value |

|---|---|

| Density | 8.4 g/cm³ |

| Melting Point | 1374-1420 °C |

| Thermal Conductivity | 15.1 W/m·K (at 100°C) |

| Specific Heat Capacity | 565.2 J/kg·K |

| Modulus of Elasticity | 224Gpa |

| Electrical Resistivity | 1.09 µΩ·m |

| Coefficient of Thermal Expansion | 12.8 x 10⁻⁶ /°C (20-100°C) |

| Property | Value |

|---|---|

| Tensile Strength | ≥785Mpa |

| Elongation | ≥35% |

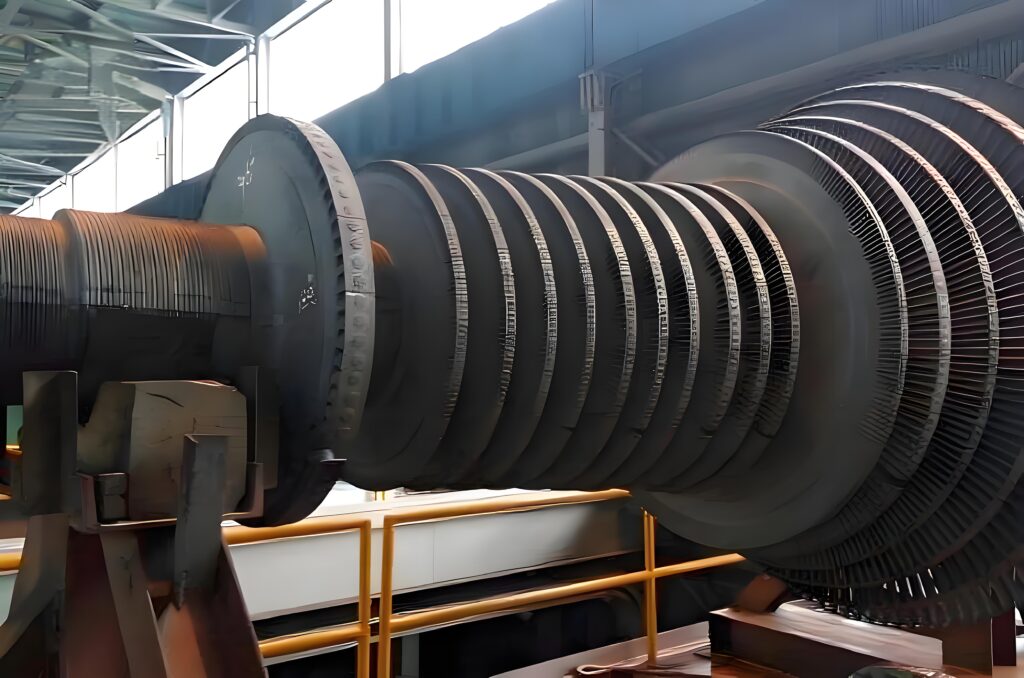

(1) Mainly used for turbine engine combustion chamber components operating below 800°C

(2) Other high-temperature parts that require oxidation resistance below 1100 ℃ but bear small load

(3) Used to make a mobile firing frame in the enamel furnace

(4) GH3030 has strong hot and cold processing properties and is used to make various chemical equipment and supporting accessories.

Copyright 2007 – 2024 |Shanghai Starway Metal Technology | All Rights Reserved | Powered by starway |