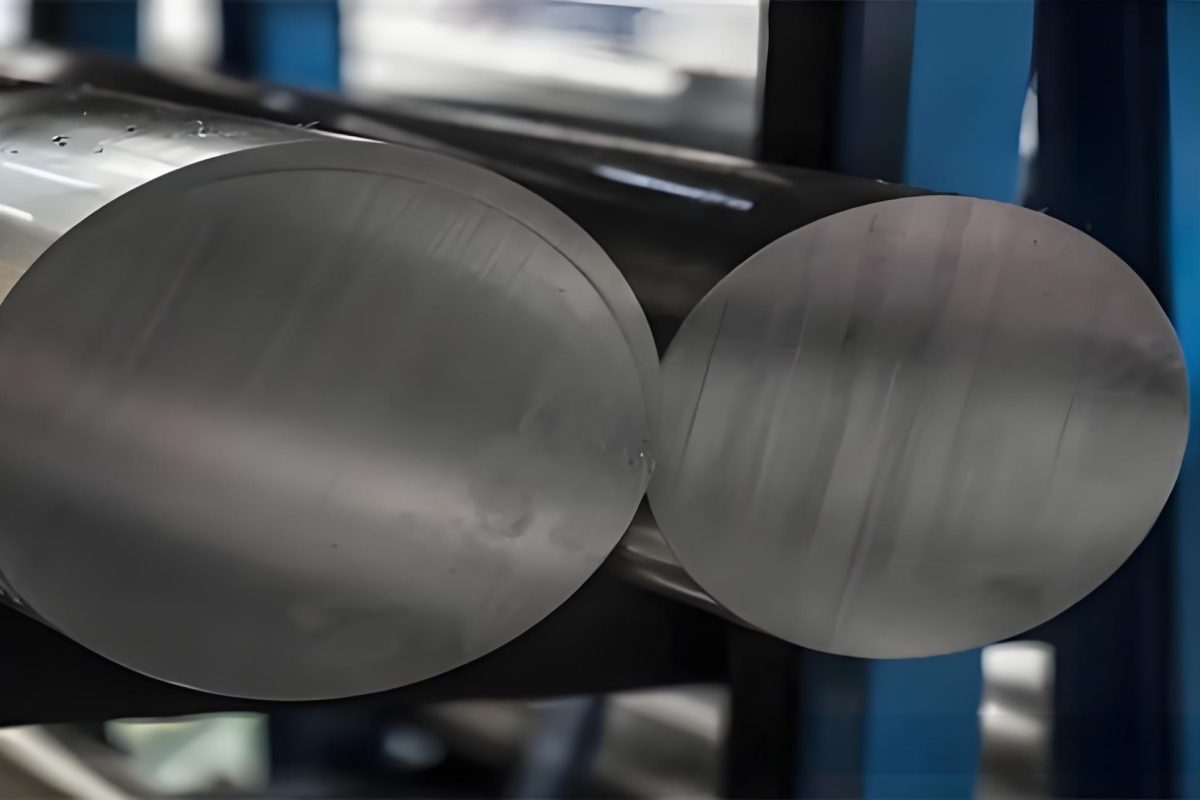

GH4141 is a precipitation hardening nickel-based deformation high temperature alloy. It has high tensile and creep strength and good oxidation resistance in the range of 650-950℃. Due to the high content of aluminum, titanium and molybdenum in the alloy, it is difficult to open the ingot, but the deformed material has good plasticity. It can be cold formed in the annealed state and can also be welded. Strain aging cracks are easy to occur during heat treatment of welded parts. The alloy varieties include thin plates, strips, wires, discs, rings, forgings, bars, and precision castings.

| Element | Minimum(%) | Maximum(%) |

|---|---|---|

| C | 0.06 | 0.12 |

| Cr | 18 | 20 |

| Ni | remiander | remiander |

| Al | 1.4 | 1.8 |

| Ti | 3 | 3.55 |

| Fe | - | 5 |

| B | 0.003 | 0.01 |

| Cu | - | 0.5 |

| Mn | - | 0.5 |

| Zr | - | 0.07 |

| S | - | 0.015 |

| Co | 10 | 12 |

| P | - | 0.015 |

Due to the high content of aluminum, titanium and molybdenum in the alloy, it is difficult to open the ingot, but the deformed material has good plasticity and can be cold-formed and welded in the annealed state. Strain aging cracks are easy to occur during heat treatment of welded parts. The alloy varieties include thin plates, strips, wires, discs, rings, forgings, bars, and precision castings, which are suitable for manufacturing high-temperature parts of aviation and aerospace engines that require high strength below 870℃ and oxidation resistance below 980℃.

Copyright 2007 – 2024 |Shanghai Starway Metal Technology | All Rights Reserved | Powered by starway |