GH4169

GH4169 alloy is a precipitation-strengthened nickel-based high-temperature alloy, in the temperature range of -253 ~ 650 ℃ has a good all-around performance, 650 ℃ below the yield strength of the deformation of high-temperature alloys in the first place, and has a good fatigue, radiation, oxidation, corrosion resistance, as well as good machining properties, good welding performance.

Able to manufacture various parts with complex shapes, in aerospace, nuclear energy, petroleum industry and extrusion molds,

It has been widely used in the above temperature range.

Content

Chemical composition of GH4169(%)

| Element | Composition (%) |

|---|---|

| Ni | 50.0 – 55.0 |

| Cr | 17.0 – 21.0 |

| Fe | Balance |

| Mo | 2.8 – 3.3 |

| Ta | 4.75 – 5.5 |

| Ti | 0.65 – 1.15 |

| Al | 0.2 – 0.8 |

| Co | ≤ 1.0 |

| Mn | ≤ 0.35 |

| Si | ≤ 0.35 |

| S | ≤ 0.015 |

| P | ≤ 0.015 |

| C | ≤ 0.08 |

| Cu | ≤ 0.3 |

| B | 0.001 – 0.006 |

Physical properties of GH4169

| Property | Value |

|---|---|

| Density | 8.19 g/cm³ |

| Melting Point | 1260 – 1320 °C |

| Thermal Conductivity | 11.2 W/m·K (at 20°C) |

| Specific Heat Capacity | 435 J/kg·K (at 20°C) |

| Electrical Resistivity | 1.25 µΩ·m (at 20°C) |

| Coefficient of Thermal Expansion | 13.0 x 10⁻⁶ /°C (20 – 100°C) |

| Young’s Modulus | 204 GPa |

| Poisson’s Ratio | 0.29 |

Mechanical properties of GH4169 alloy

| Property | Value |

|---|---|

| Tensile Strength (Ultimate) | 965 – 1110 MPa |

| Yield Strength (0.2% Offset) | 550 – 725 MPa |

| Elongation at Break | 12 – 25% |

| Hardness | 331 – 370 HB (Brinell Hardness) |

| Impact Toughness (Charpy V-notch) | > 100 J |

| Creep Rupture Strength (650°C, 23.5 MPa) | 23.5 MPa after 1000 hours |

| Fatigue Strength | 620 MPa (at 10⁷ cycles) |

Applications of GH4169

1. Aerospace Industry

- Turbine Blades and Vanes: The alloy’s ability to retain strength and resist creep at high temperatures makes it ideal for turbine blades and vanes in jet engines.

- Rocket Motors and Engine Components: Its high strength and resistance to thermal and mechanical fatigue make it suitable for critical components in rocket engines.

- High-Temperature Fasteners: Used in aircraft due to its excellent mechanical properties and oxidation resistance.

2. Power Generation

- Gas Turbine Components: GH4169 is used in various parts of gas turbines, including discs, shafts, and casings, due to its ability to withstand high temperatures and resist oxidation and corrosion.

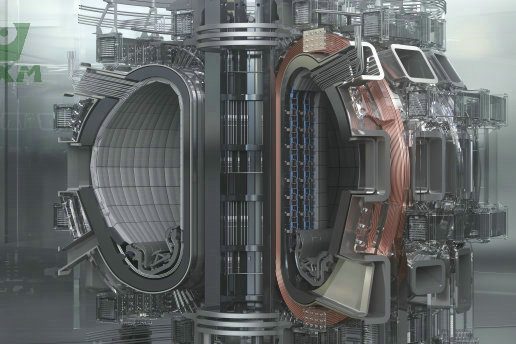

- Nuclear Reactors: Its resistance to radiation damage and high-temperature performance make it suitable for use in nuclear reactors, particularly in control rods and other components exposed to high temperatures and radiation.

3. Oil and Gas Industry

- Downhole Tools: Used in oil and gas exploration and production equipment, such as downhole tools, due to its resistance to sulfide stress cracking and corrosion in harsh environments.

- Subsea Equipment: GH4169’s corrosion resistance and high strength make it ideal for subsea valves, connectors, and fasteners.

4. Automotive Industry

- Turbocharger Components: The alloy’s high-temperature strength and oxidation resistance are beneficial for turbocharger rotors and other components exposed to extreme temperatures.

- Exhaust Systems: Used in high-performance exhaust systems where high strength and resistance to thermal fatigue are required.

5. Marine Applications

- Propulsion Systems: Utilized in marine propulsion systems where resistance to corrosion and high mechanical strength are essential.

- Submarine Components: Its excellent corrosion resistance in seawater and high strength make it suitable for critical submarine components.

6. Industrial and Chemical Processing

- Heat Exchangers: GH4169 is used in heat exchangers that operate under high temperature and corrosive conditions due to its resistance to oxidation and sulfidation.

- Pressure Vessels: The alloy’s mechanical properties and corrosion resistance make it suitable for pressure vessels in chemical processing industries.