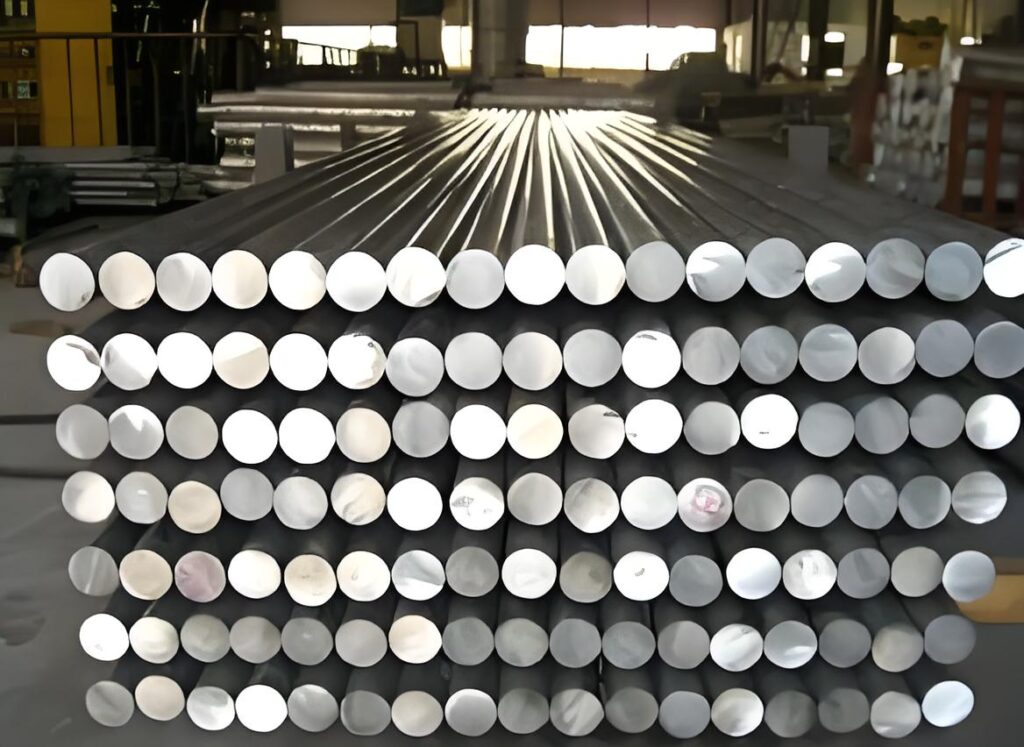

Incoloy825

Incoloy825 is a fully austenitic nickel-iron-chromium alloy stabilized with titanium, with additions of copper and molybdenum. Incoloy 825 is a general purpose engineering alloy that resists acid and alkali corrosion in both oxidizing and reducing environments.

Content

Chemical composition of Incoloy825(%)

| Element | Minimum(%) | Maximum(%) |

|---|---|---|

| Ni | 38 | 46 |

| Cr | 19.5 | 23.5 |

| Fe | remiander | remiander |

| C | - | 0.05 |

| Mn | - | 1 |

| Si | - | 0.5 |

| Cu | 1.5 | 3 |

| Mo | 2.5 | 3.5 |

| Al | - | 0.2 |

| Ti | 0.6 | 1.2 |

| P | - | 0.03 |

| S | - | 0.03 |

Physical properties of Incoloy825

| Value | Property |

|---|---|

| Density | 8.14 g/cm3 |

| Melting range | 1370-1400℃ |

Mechanical properties of Incoloy825 alloy

| Value | Property |

|---|---|

| Tensile Strength | 550 MPa |

| Yield Strength (0.2% Offset) | 220 MPa |

| Elongation | 30% |

| Hardness(HB) | ≤200 |

Applications of Incoloy825

Incoloy 825 is a versatile nickel-iron-chromium alloy with good resistance to oxidation, corrosion, and a broad range of chemicals, thanks to its composition which includes molybdenum, copper, and titanium. The unique properties of Incoloy 825, such as its resistance to sulfuric and phosphoric acids and its ability to avoid pitting in chloride environments, make it suitable for specific applications across various industries. Here are some key applications that leverage the unique properties of Incoloy 825:

- Oil and Gas Industry: Incoloy 825 is widely used in the oil and gas industry for piping, valves, pumps, and other components exposed to corrosive substances, especially those containing sulfuric and phosphoric acids.

- Chemical Processing: The alloy’s resistance to a wide range of chemicals makes it ideal for reactor vessels, heat exchangers, and piping systems in chemical processing plants, especially where acidic environments are common.

- Pollution Control Equipment: Incoloy 825 is used in flue-gas desulfurization systems and other pollution control equipment due to its resistance to oxidizing and reducing agents.

- Marine Applications: Its resistance to pitting and crevice corrosion in seawater and marine environments makes it suitable for parts in shipbuilding and repair, such as propeller shafts, oil rig components, and seawater-cooled heat exchangers.

- Nuclear Applications: Incoloy 825 is used in nuclear fuel reprocessing and waste handling systems due to its resistance to nuclear acids.

- Acid Production: Its resistance to sulfuric and phosphoric acids is valuable in equipment used in acid production, such as piping, tanks, and heat exchangers.

- Power Generation: Incoloy 825 is used in superheaters, re-heaters, and other components in power plants due to its ability to withstand high temperatures and corrosive environments.

The alloy’s combination of high nickel content with molybdenum and copper provides excellent resistance to a variety of corrosive environments, while the addition of chromium contributes to its oxidation resistance. These properties make Incoloy 825 a preferred material for demanding applications where both corrosion resistance and high strength are required.