Monel 400

Monel 400 (UNS N04400, NCu30) The organization of Monel 400 alloy is a high-strength single-phase solid solution, which is one of the most used, most versatile, and excellent all-around corrosion-resistant alloys. This alloy has high quality corrosion resistance in hydrofluoric acid and fluorine gas media, and also has excellent corrosion resistance to hot concentrated alkaline solutions. It is also resistant to corrosion from neutral solutions, water, seawater, atmosphere, organic compounds, and so on. An important feature of this alloy is that it is generally free from stress corrosion cracks and has good cutting properties.

Content

Chemical composition of Monel 400(%)

| Element | Minimum(%) | Maximum(%) |

|---|---|---|

| Ni | 63 | - |

| Cu | 28 | 34 |

| Fe | - | 2.5 |

| Cr | - | 0.3 |

| Mn | - | 2 |

| Si | - | 0.5 |

| S | - | 0.024 |

Physical properties of Monel 400

| Property | Value |

|---|---|

| Density g/cm3 | 8.83 |

| Melting range ℃ | 1300-1390 |

Mechanical properties of Monel 400 alloy

| Property | Tensile Strength ksi | Yield Strength (0.2% Offset)MPa | Elongation % | Hardness Brinell(3000-kg) | Rockwell B | ||

|---|---|---|---|---|---|---|---|

| Bar | 70-110 | 480-760 | 25-85 | 170-585 | 50-5 | 110min | 60min5 |

| Plate | 70-95 | 482-655 | 28-75 | 193-517 | 50-30 | 110-215 | 60-96 min |

| Sheet | 70-120 | 482-827 | 30-110 | 207-758 | 45-2 | - | 65min |

| Belt | 70-140 | 482-965 | 25-130 | 172-896 | 50-2 | - | 68min |

| SMLS pipe | 70-130 | 482-896 | 25-110 | 172-758 | 50-3 | - | 100max |

| Cold drawn wire | 70-180 | 482-1241 | 30-170 | 207-1172 | 45-2 | - | - |

Applications of Monel 400

Monel 400’s unique properties, particularly its excellent resistance to corrosion, high strength, and ability to remain ductile at sub-zero temperatures, make it suitable for various specialized applications. Here are some key applications that leverage these unique characteristics of Monel 400:

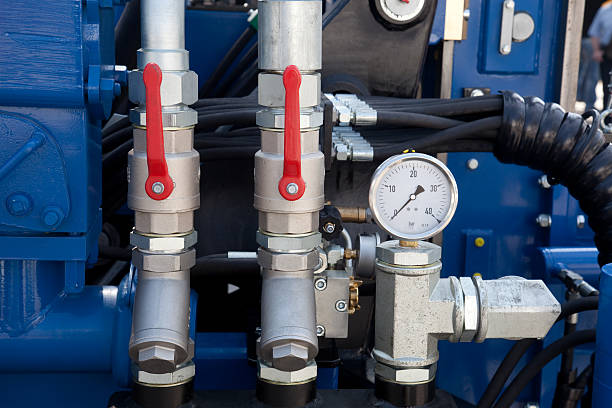

Marine Engineering: Monel 400 is extensively used in marine engineering due to its exceptional resistance to seawater corrosion. It is utilized for marine fixtures and fasteners, boat shafts, and propellers. Its resistance to saltwater makes it an ideal choice for these applications.

Chemical Processing Industry: Due to its excellent resistance to a wide range of acids and alkalis, Monel 400 is used in chemical processing equipment. It is suitable for handling hydrofluoric acid, sulfuric acid, and hydrochloric acid, among others, used in reactors, heat exchangers, and pumps.

Petroleum Industry: Monel 400 is used in the oil and gas industry, especially in applications like valves, pumps, and piping systems that are exposed to sour gas. Its resistance to stress corrosion cracking in the presence of hydrogen sulfide is particularly valuable.

Desalination Plants: In desalination plants, Monel 400 is used for its corrosion resistance to high-velocity seawater, making it suitable for tubing and other components.

Aerospace Industry: Its high strength and resistance to corrosion make Monel 400 a good choice for certain aerospace applications, including as part of the fuel and hydraulic line systems.

Electronic and Electrical Applications: Due to its low electrical conductivity relative to other metals, Monel 400 is used in electrical and electronic applications, particularly in the manufacturing of precision resistors and other components where its properties can be advantageous.

Cryogenic Applications: Monel 400 retains its mechanical properties at very low temperatures, making it suitable for cryogenic applications. It is used in equipment handling liquefied gases like liquid oxygen, nitrogen, and natural gas.

These applications highlight the versatility of Monel 400, leveraging its unique combination of corrosion resistance, strength, and ductility in challenging and aggressive environments.